Glossary

Mechanical finish

Mechanical finishing processes are a physical treatment on the fabrics. The finishes may be obtained by using heat or liquids on the materials (decatising) to render it matte or shape it. The use of, originally manual tools, but today specifically shaped cylinders which can be used for shearing, scraping or calendering to obtain a fabric or wool which is fluffy, warm, glossy or even silky. The moiré technique produces light-reflective shimmering materials.

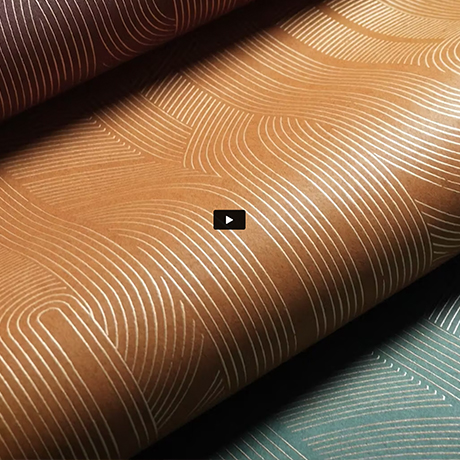

Moiré / watermarked

Moiré (or watermarking) is a mechanical finishing to add a wavy look by calendering. The surface is transformed by crushing the yarns in opposite directions giving it a changing appearance depending on the light. Light is reflected by the flat surfaces of the fabric giving a metallised, mirrored look. This shimmering effect can be obtained on tightly-woven fabrics with a pronounced grain such as ottoman, grosgrain or faille.

Madras

Madras fabric is of Indian origin, first made with banana-plant fibres then silk or cotton. Today it is a fabric with a silk warp and a cotton weft with bright colours with checked or striped patterns.

Mohair

Mohair is made from the coat of the Angora goat. It has excellent insulating properties and is moisture-resistant. The structure of the fibres is extremely complex and when woven or knitted is breathable and glossy. The purest and finest mohair is used in making upholstery fabrics.

Muslin / chiffon

Muslin or chiffon, is a loosely woven cotton fabric from Bangladesh, imported through the Indian port of Machilipatnam, known by the Romans as Maisolos. Muslin or chiffon is the name given to all lightweight fabrics of silk, cotton, wool or other fibres. These fibres are suitable for use as drapes, both voiles or curtains.

ME - Metal