Glossary

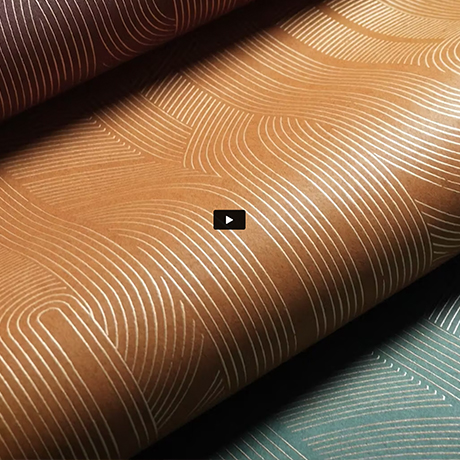

Rotary screen printing

Rotary screen-printing uses metal rollers that take the place of stencils as for flat frame printing. The cloth moves automatic in a horizontal motion on a conveyor to allow continuous printing of the pattern colours one after the other. A mechanism forces the colour through the perforated rollers to mark the fabric.

Reserve or resist printing/dyeing

Reserve printing are modern methods using traditional techniques such as the Uzbek Ikat. Certain parts of the yarns or fabric are partially covered, originally with wax, today a printing paste is used to stop the colourants penetrating according to the patterns required. Physical treatment uses a resin which protects the fabric from the colourants during the dyeing process of the fabric piece. Chemical treatment produces the same result by means of interaction between the colourants and the product used. The washing then eliminates the applied product (called the resist).